How To Fix Rust Spots On Your Vehicle

An ominous brown stain on the fender. A chimera in the paint at the bottom of a door. Soaked floors after hitting a puddle. These are signs the iron worm has been hard at work: rust.

Otherwise fine cars are routinely sent to early graves because the get rusty cars, even though it'due south a largely avoidable problem. With atomic number 26-based metals, battling oxidation can feel like a Sisyphean task. In spite of the advanced coatings and alloys developed by chemists and engineers, iron'southward unstable chemical makeup means it will always succumb to rust in a natural environment. In fact, iron and nigh steel will completely reduce to iron oxide and other elective elements over a long enough fourth dimension.

This doesn't mean that your motorcar is doomed! Understanding how cars become rusty, your machine'south problem areas, and how auto rust tin can be repaired from that brown, flaky problem ways that your pride and joy tin can stay on the road equally long as you practise.

More From Popular Mechanics

Why are cars rusty?

Rust forms as a result of the electrochemical breakdown of iron-based metals. This breakdown is the result of oxidation, which is the procedure where iron surface molecules react with oxygen in the environment and produce a new molecule, Fe2O3, otherwise known as iron oxide. That iron oxide is rust.

Pure iron doesn't oxidize as aggressively. Examine an quondam iron engine cake and you'll run into a sparse surface layer of rust simply little penetration into the metal. Unfortunately, iron alone isn't a particularly good fabric for edifice cars, so today's cars typically utilise steel alloys. Adding a dollop of carbon to iron creates steel, which offers dramatic improvements in flexibility, tensile strength, and formability. However, this added strength comes at a toll, as it adds impurities that accelerate the formation of rust.

Exposed steel rusts at different rates depending on several factors: blend components, thickness, the environs the steel lives in, and the type of heat treating the steel undergoes. Very poorly fabricated cars in the 1970s began showing surface rust as soon as they hit the docks. Completely untreated raw sail steel can rust through in as little as a few years.

Then there's the upshot of salt. Road salts and other contaminants dissolved in water human activity as electrolytes. When electrolytes are introduced to a chemic reaction, they speed up the substitution of molecular components. For drivers, this means that dirty or salty water trapped somewhere in the auto'due south body makes that spot rust faster. It also explains why cars in northern climates where table salt is used in winter besides as cars that spend a lot of time near the bounding main are prone to rot.

This is why automakers do then much to try and prevent corrosion. A huge corporeality of testing and material scientific discipline is dedicated to keeping your car from dissolving abroad beneath you. Aluminum and magnesium components are condign popular not simply considering of their lite weight, but also because they corrode at rates that are unnoticeable inside a human lifetime. Still, those metals are expensive and automakers use them sparingly equally a result.

Alloying elements added into cars' steel such as nickel and chromium can help stave off rust, but aught is foolproof—everything eventually corrodes. Mod sheet steel too comes off the ringlet with highly durable coatings. Those are farther augmented in the final associates plants when freshly made vehicle bodies are dipped in baths of anti-corrosion agents earlier the painting process.

All the same, the road-facing side of the car turns into one big sandblasting cabinet at highway speeds, and those dips and coatings wear off over time. This is why every motorcar owner needs to periodically inspect their automobile for rust regardless of where it lives or what kind of boosted underbody coating it may have come with.

How to repair car rust

Rust forms in stages, and knowing where a problem spot is in that decomposition process can help bespeak you to the right solution. Here are the iii main stages of rust and how to gear up them.

Surface Rust

The first signs of a problem popular up in paint nicks, cracks, and scratches. An easy gear up.

Surface rust is just that: on the surface. Go out a car with steel disc brake rotors parked for a piddling while, and you can come across surface rust class on the rotors. That's never a threat, however, every bit that rust is typically wiped off the rotor subsequently but a few stops.

Near surface rust on your machine forms when paint breaks down through mechanical or UV damage, which is why fifty-fifty cars in warm, dry climates become information technology. Structurally, surface rust is not a problem, and depending on the metal'south thickness and alloy limerick, a level of "passivation" may even be reached where the surface rust actually guards the metal from further oxidation.

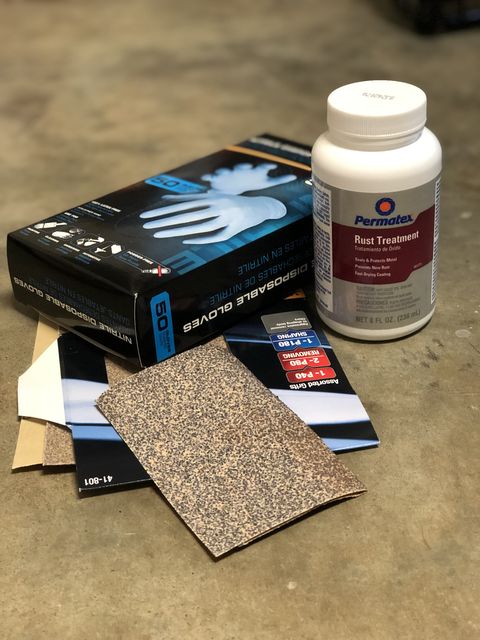

Regardless, information technology's best to correct surface rust as soon every bit you meet it—but in case. That patina-coated truck from Arizona may get a pigsty-filled nightmare in the wrong weather. The gear up is much like general paint repair. Start by using an abrasive wheel or sandpaper (nosotros used 50-grit) to cut through the paint and corrosion until make clean, bright metal is visible. Rough upwards the surrounding areas, too, and then that your body treatments can adhere well to the car.

Next, use a rust inhibitor or converter to impede the tin can worm'due south progress. Your steel may look shiny after knocking the visible rust off, but there'southward yet some iron oxide there. Rust inhibitors convert iron oxide into a chemically stable, wet-resistant compound that protects the rest of the metallic underneath. For instance, the Permatex Rust Handling we tried contains tannic acid, which reacts with the rust and converts it to iron tannate (which is stable) and two-Butoxyethanol, an organic polymer that acts as a primer atop the metallic. (You tin can paint over this Permatex version, merely nosotros recommend this one for places like the motorcar's underbody where you don't intendance how it looks as long as it's not rusting.)

Then put on some prophylactic gloves and utilise the rust converter with a brush or sponge. You'll desire to cascade every bit much rust converter as yous think you'll use into a disposable container because you can't double-dip into the bottle. If you get some rust in your container of rust converter, the compounds will get-go working there instead of on your auto'due south metallic, thus ruining the contents of the bottle. Wipe a thin layer of rust converter onto the metal and expect fifteen to 30 minutes for it to dry.

Then add a 2d layer and await at least a one-half hour for it to dry. If yous tin can proceed the surface moisture-free for 24 hours, then you could prime number it—this Permatex Rust Treatment isn't a primer for paint. Follow upwardly that primer with paint and clearcoat, then buff to alloy the finishes. Alternately, if it's in a spot where people can't see, yous can just go out it lone after letting the Permatex Rust Treatment (or similar sealing rust converter) dry, secure in the knowledge that your winter beater might concluding a few more seasons without the bumpers falling off.

Scale Rust

The chemic procedure corrupts the surface and reduces metal strength.

If you don't correct surface rust and you allow that decomposition to penetrate farther into the metal, yous may encounter bubbles commencement to form in your car's paint. This is because iron oxide molecules are physically bigger than those of atomic number 26 or steel. That worsening rust consequence cocky-propagates by expanding and flaking away the outer layers of paint and metal, exposing fresh base metal, which and so corrodes.

When rust penetrates into the surface like this, information technology causes a rough, pitted type of impairment chosen scale. Correcting scale means getting through the rust with a wire castor, knocking down roughness with a grinding bicycle and smoothing out the surface with sandpaper. Make sure you're down to bare metal and that at that place are no big flakes of rust left before sealing it support, otherwise your sealer or filler could pop right dorsum off. Rough upward the surface area around the blank metal so your next sealants and treatments can stick to information technology. If it's in a nondescript area such as underneath the auto, you tin can only seal this cleaned-up spot support with a rust converter and call it a solar day.

The metal surface may still be rough once you're done sanding the larger flakes off. If it's in a more than visible spot, you may want to consider smoothing it out with a body filler such as Bondo earlier finishing it out with primer and paint. Follow the instructions from the manufacturer of the body filler every bit it can vary, only generally speaking, you mix it up to a specified ratio depending on your room temperature. NAPA recommends simply mixing as much body filler as you'll utilise within ten minutes as information technology starts to harden relatively apace. Spread it on using a metal or plastic spreader, simply exit a fiddling actress on acme to sand smoothen.

It takes about xxx minutes for Bondo to fully cure and harden. Later that, smooth out the extra filler yous left on summit and then the repair matches the contours of the rest of the car. If you have a rust inhibitor that is safety to utilise with body filler, add this now, but otherwise, you can seal your work with a regular, loftier-quality primer. As with fixing surface rust, paint and clear-glaze your repaired spot, and then buff to alloy it in with the rest of the car.

Penetrating Rust

Later prolonged exposure, steel is converted to brittle iron oxide and holes grade.

Rust volition eventually swallow through your car'south metal if left unchecked. This is penetrating rust, and it's the cause of everything from Swiss cheese-manner holes in the fenders to more than dangerous issues with weakened frames and suspension components.

If you live somewhere with rust-decumbent conditions, don't await for bubbles to appear on your car's body. Take a look underneath the motorcar periodically to audit for any rough or compromised parts that could be a safety risk on the road if left unfixed.

Every bit scale rust gets worse, the base metal flakes away and leaves holes. Now y'all've got a bigger problem, and you've got 2 options to fix it. You tin can completely replace the affected part or panel (tough), or if information technology's just a bodywork effect, y'all tin can cut the rotten parts out and weld metal "patch panels" into place (tougher). A reputable trunk store should exist able to take care of either consequence. Welds that concord on patch panels can be smoothed out to expect similar they were always office of the car by the right set of talented easily.

As tempting as it may exist, you shouldn't repair these larger holes with trunk filler as you would with pits left by scale rust.

That being said, don't attempt to patch your auto'southward frame back together. A rusted-through frame means the structural integrity of the car is questionable, and it should be inspected and repaired past a qualified repair facility. You really don't want to be in a crash in a structurally sketchy machine, and so we can't reiterate this plenty: check for rust underneath your vehicle every at present and so—before information technology's too late.

How to stop rust from forming

The good news is that this kind of vehicular decay is largely preventable. The best advice is the nearly obvious: Launder your motorcar regularly to go on the body and underside clean of the road grime, salts, and dirt that lead to corrosion. Many modern car washes can blast the underside of your car with water to get much of this grime off.

The not-so-obvious advice is to check the drain holes along the bottoms of doors and rocker panels, which allow rainwater to flow out. Apply a pipe cleaner to clear these holes out, and go on the car's nooks and crannies dry out. WD-xl can be a useful tool here as well. This lubricant protects parts from corrosion, and its sparse nozzle can be used to reach tight underbody spots and boom away water or corrosive crud.

Every bit noted before, many vehicles have a thick coating on the underside that chemically seals the steel against oxidizing agents. Regular inspection and repair of the spots that accept worn blank will keep rust from advancing and causing boosted damage. If this coating is non there, consider adding one yourself. POR-xv is one of the more than pop examples of such a rust-protective sealant, and they even accept a rubberized coating to get over it in case you desire even more protection underneath your machine. As with other rust repairs, sand off whatever rust that might be sticking through and rough upwards the area you intend to paint with some sandpaper, then brush or spray the new coating on.

Every bit long equally your metal is properly sealed from the elements and kept clean of corrosive salt and grime, you should be able to become years of safe driving out of fifty-fifty the most abused winter beater.

Stef Schrader routinely breaks and attempts to take project cars on race tracks. She enjoys fancy cheeses, skillful java, fast Porsches, traveling to new places and rare, weird cars. She lives with a big collection of Fisher-Price Puffalumps and an overloaded parts shed.

How To Fix Rust Spots On Your Vehicle,

Source: https://www.popularmechanics.com/cars/how-to/a3084/how-to-fight-rust-and-win-14930616/

Posted by: jacksonhipild.blogspot.com

0 Response to "How To Fix Rust Spots On Your Vehicle"

Post a Comment